Home » Experts in Cellular Materials » CellMat Innovative Approach

Experts in Cellular Materials

CellMat Innovative Approach

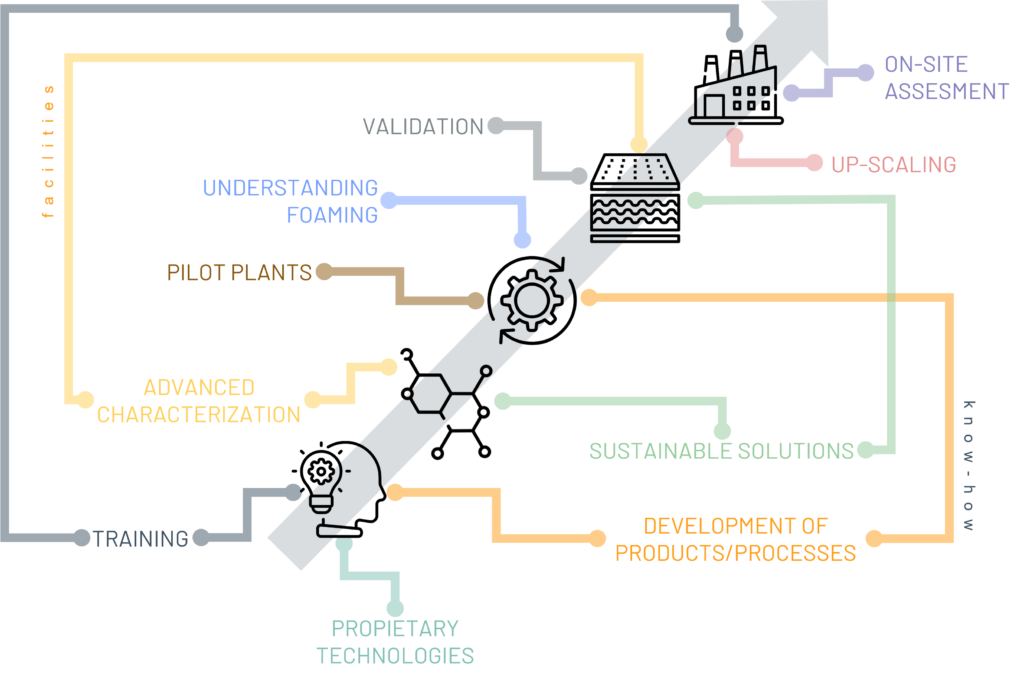

Our approach is based on offering a turn-key R&D service providing solutions in all the stages of the loop: creating, developing, optimizing, and validating the new processes and products targeted for the foam industry. Our specific know-how in this field assisted us in developing a special working methodology able to meet the requirements of our customers without interfering in their production processes. We manage to achieve short-term measurable benefits to help our industrial partners to improve their competitiveness.

The beginning – the smart idea

Novel applications, more versatile products, or advanced versions of the current ones trigger the need for new ideas and formulations. We apply our know-how or even our proprietary technologies to design and provide the best formulations to address each specific challenge. By being in touch with the latest innovations, we provide tailor-made training courses that will promote your personnel and will help them to come up with the best new ideas.

The basis – the raw materials

The selection of raw materials is a critical point to create formulations with proper foamability. We are specialists in developing formulations aimed at foaming applications for different applications. we offer guidante to raw material producers by testing their products using our lab devoted to advanced characterization and therefore defining the best potential environment for the usage of their products (polymers, blowing agents or additives). We are also experts in offering more sustainable solutions ranging from recycled polymers, biopolymers, greener blowing agents, etc.

The fabrication process – our pilot plants

Downgaging to maximize the outcome and accelerate toward new possibilities. We have pilot plants capable to replicate all the industrial processes at a downsized scale: extrusion foaming, crosslinked foams, bead foaming, reactive foaming, etc. The usage of pilot plants allow the fast testing of formulations, saving raw materials cost and time in comparison to industrial trials. Additionally, we can contribute to new developments using our experience in designing specific processes for any application.

The foam and the foaming process - in and out!

Our many years of experience in the foams field has resulted in a set of tools developed to understand the foaming process. From rheological measurements of the raw materials to in-situ monitoring the process by X-Ray radioscopy. We have learned how to look inside the foam. We also offer full characterization services of the foam characteristics (determination of the foam density, analysis of the cellular structure, evaluation of the open cell content, etc.) and properties to validate the prototypes, or your foam products: mechanical, thermal, acoustic, fire resistance, etc.

Ready to go! – the scaling up

How to move from an R&D development to real life? We offer our support and strong experience in this matter to help our partners in this last stage of the process. Machinery advice and design, adjustments in the formulation and processing conditions, on-site assesment, validation of large-scale prototypes: our expertise at your service from the beginning to the end!